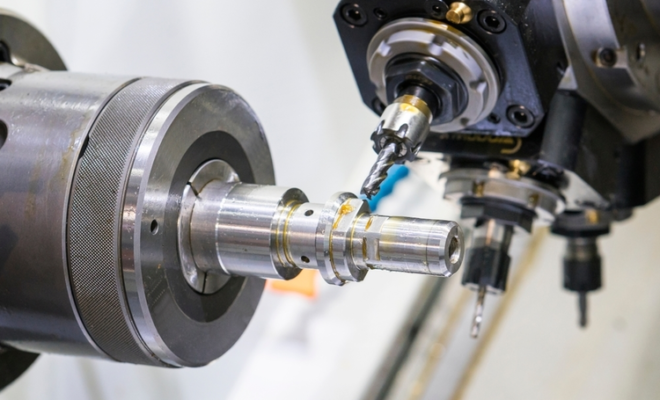

All You Should Know About Metal Fabrication Processes& Tools

Metal fabrication is a detailed process involving multiple steps. It employs various tools to shape and join metal sheets to form different structures and materials. It involves deforming raw materials, and fabricators are handy in every step of the process. If you’re a beginner metal fabricator, you may want to learn more about the processes and the tools involved.

Here are essential things to know about metal fabrication.

- Metal fabrication involves multiple steps.

Metal fabrication entails several steps. These range from cutting or shearing, forming, machining, welding, and more. The time taken is typically determined by the meticulous planning and execution of the processes. This makes it vital to have the right tools to save time on your project.

It also involves secondary processes other than the usual cutting, shaping, and assembling. The typical secondary procedures may include anodizing, galvanizing, sandblasting, plating, and finishing.

- Metal fabrication demands different tools & equipment.

The process necessitates a variety of tools. A metal fabricator may employ a table saw, press brake, lathe, or grinder while undertaking most tasks. However, all jobs are unique, and the equipment required will vary between projects. No matter the type of equipment, any reputed Metal Fabrication Tool Distributer will advise you to acquire the tools from legitimate stores.

- There are limitations to the fabrication processes.

Contrary to common belief, a metal fabricator can change an item at any time. Like many other processes, metal fabrication has its fair share of limitations. There are multiple regulations regarding shop equipment, materials, and access to some procedures.

For instance, a shop might be able to handle all of the main metal fabrication works but still need to send pieces out for finishing. Alternatively, a fabricator may discover that the design parameters are incompatible with the needed material. In this case, they may require a different material.

- All fabrication materials are different.

Metal fabricators are responsible for not only completing the job but also for determining which fabrication procedures are most effective. Understanding the best material is a significant part of that.

Although all metals may seem the same, they all have unique characteristics and uses. For instance, tensile strength, formability, and weldability are all aspects to consider because these vary from one metal sheet to another. Aluminum, for example, has a lower melting point than stainless steel, which makes it versatile and easy to use.

Where can I get the best metal fabrication distributor?

The best way to locate a leading metal fabrication shop is to search online. There are many online stores dealing with such tools, and shopping online allows you to compare the devices, features, and prices with ease. You can also seek recommendations from loved ones. However, visit the company’s website and get more information about the quality of products before purchasing.

In summary, metal fabrication involves various processes and employs a set of quality tools and equipment. No matter the process, always acquire what you need from legitimate sites. By so doing, you’ll get quality tools and save a lot of money in the long run.